The Evolution of the BMW Engine: A Look Back at Iconic Models

The Evolution of the BMW Engine: A Look Back at Iconic Models

Blog Article

A Thorough Evaluation of Engine Performance Enhancements With Advanced Gas Injection Solutions

In the realm of vehicle engineering, the assimilation of sophisticated gas injection systems has revolutionized the landscape of engine performance. These sophisticated systems have transcended conventional gas shipment devices, providing a myriad of benefits that prolong past simple burning performance. By carefully managing the fuel-air combination and shot timing, these cutting-edge technologies have opened a realm of opportunities for enhancing engine abilities. The elaborate interaction in between fuel shot systems and engine performance is a topic of profound significance, clarifying the nuanced complexities that regulate contemporary propulsion. As we start a journey to explore the midsts of these advancements, we are poised to decipher the intricacies that underpin the development of vehicle giants.

Advancement of Fuel Injection Technology

Throughout the history of vehicle design, the evolution of gas shot technology has actually been noted by significant innovations in effectiveness and performance. Fuel injection systems have actually come a long way since their inception, with the earliest versions being mechanical and less accurate. The shift from carburetors to digital gas injection (EFI) systems changed the industry by offering extra accurate fuel shipment, leading to improved engine efficiency and reduced exhausts.

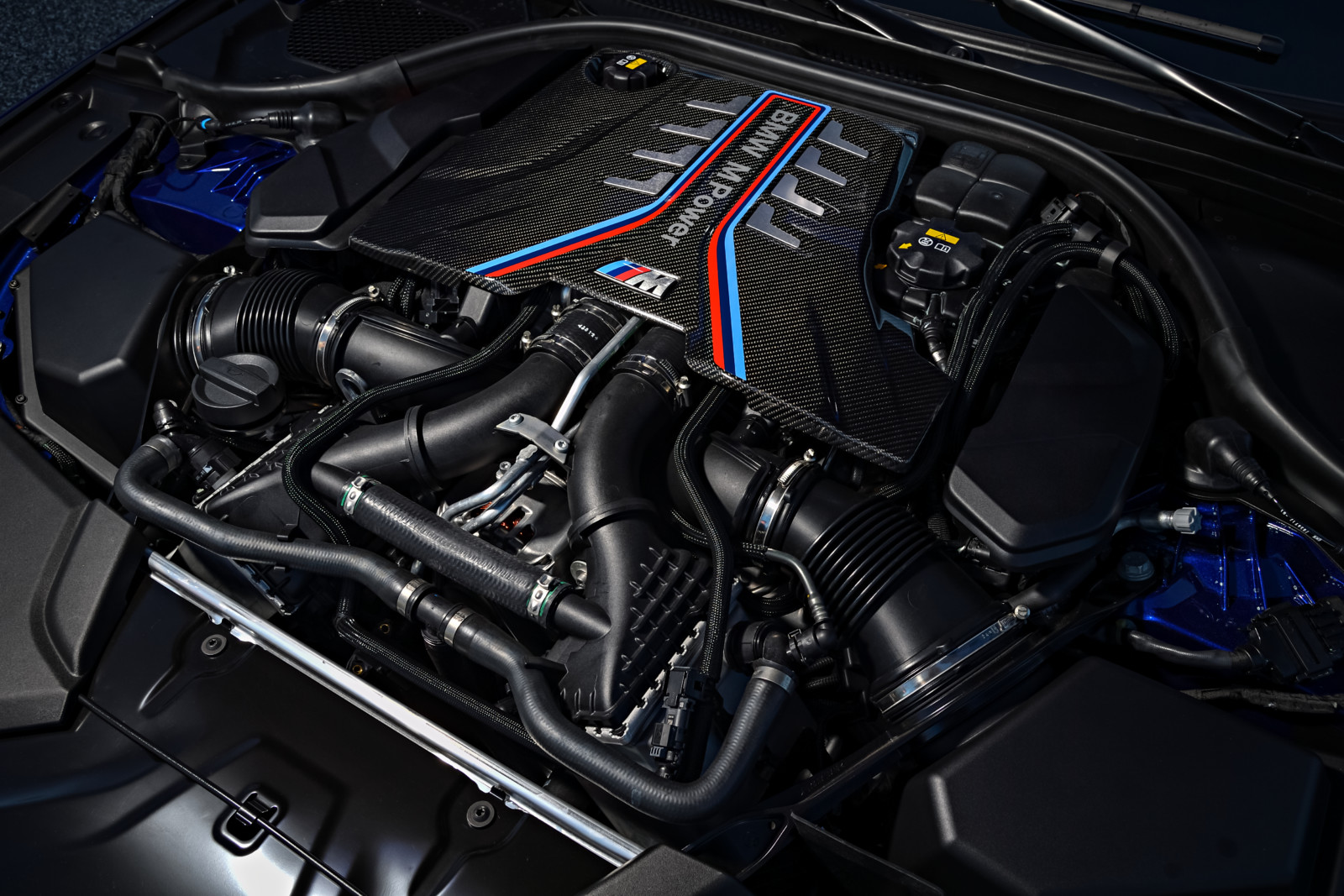

The following major landmark in gas shot technology was the introduction of straight gas injection (DI) systems. DI systems further boosted engine efficiency by infusing gas directly right into the burning chamber at higher pressures, bring about far better gas atomization and burning. This enabled raised power outcome while maintaining fuel effectiveness, an important balance in contemporary automobile engineering.

As innovation remains to breakthrough, the assimilation of features such as fuel direct shot (GDI) and stratified fuel injection systems has additionally fine-tuned the efficiency and performance capacities of contemporary engines. These developments in gas injection technology have played a crucial duty in forming the vehicle industry, driving in the direction of cleaner, more effective, and fuel-efficient vehicles.

Benefits of Advanced Gas Injection

With advancements in fuel shot modern technology, modern-day engines have experienced significant enhancements in effectiveness and efficiency. The advantages of sophisticated gas injection systems are multifold. These systems give precise control over the quantity and timing of gas delivery right into the burning chamber, resulting in optimized fuel-air combination ratios. This results in boosted fuel effectiveness, lowered emissions, and improved power output. Secondly, progressed gas injection systems add to much better throttle feedback and smoother engine operation as a result of their ability to supply fuel much more properly under differing driving conditions. In addition, these systems make it possible for better cold-start performance, as they can change gas distribution based upon engine temperature level and ecological factors. Additionally, progressed gas shot systems improve general engine dependability and long life by making certain consistent burning procedures (bmw engine). In general, the adoption of advanced fuel injection technology offers substantial advantages in regards to performance, performance, exhausts decrease, and engine sturdiness, making it a critical part in contemporary vehicle engineering.

Effect On Engine Performance

Enhancing engine efficiency with the optimization of gas shot systems is a critical element of modern-day engine development and performance enhancement. By specifically controlling the amount of fuel infused right into the burning chamber and the timing of shot, modern fuel injection systems can substantially boost the overall efficiency of the combustion procedure.

Furthermore, advanced fuel injection systems can improve engine effectiveness by giving far better atomization of the fuel, guaranteeing a much more also circulation of gas beads within the burning chamber. This boosted atomization cause an extra efficient and cleaner burn, ultimately resulting in higher fuel efficiency and power output. Additionally, the ability of advanced fuel injection systems to adapt to changing motoring problems in real-time more adds to enhancing engine effectiveness. Generally, the effect of sophisticated fuel injection systems on engine efficiency is undeniable, making them an important component of modern engine technology.

Improved Power Output Possible

Optimizing the power outcome potential of engines can be attained with strategic optimization of gas shot systems. Advanced fuel shot systems play a vital function in enhancing power result by specifically regulating the fuel delivery to the engine. home By optimizing factors such as shot timing, fuel pressure, and spray pattern, engineers can adjust the burning procedure for enhanced power generation.

One key aspect of improving power result is ensuring that the engine gets the ideal quantity of gas at the appropriate time. Additionally, advanced fuel injection systems can allow multi-stage shot approaches, where gas is delivered in multiple pulses during each combustion cycle.

Applications in Performance Engineering

Fuel injection systems are essential elements in efficiency design, promoting precise control over fuel delivery advice for optimized engine operation. These systems play a vital duty in boosting engine efficiency by making certain the correct amount of gas is supplied at the correct time to make the most of power output, fuel efficiency, and emissions regulate. In efficiency design, advanced fuel injection technologies, such as direct shot and port gas injection, are commonly utilized to achieve details efficiency objectives.

In addition, gas injection systems are crucial for sustaining various other performance-enhancing technologies, such as turbocharging and variable valve timing. By functioning in tandem with these systems, gas shot innovation helps to take full advantage of the general performance potential of modern-day engines in various applications, including auto, aquatic, and aerospace markets.

Final Thought

Finally, progressed fuel shot systems have significantly boosted engine performance by boosting effectiveness and power output. visit this page The advancement of fuel shot technology has actually paved the method for applications in performance design, offering a variety of benefits. With these improvements, engines are able to run better, leading to boosted performance abilities. On the whole, the impact of innovative fuel injection systems on engine efficiency is undeniable and proceeds to drive technologies in the automobile sector (bmw engine).

By specifically controlling the amount of fuel injected right into the burning chamber and the timing of injection, modern fuel injection systems can substantially boost the total efficiency of the combustion process.Additionally, progressed gas shot systems can boost engine performance by providing better atomization of the fuel, guaranteeing a much more even distribution of fuel droplets within the combustion chamber. Additionally, advanced fuel injection systems can enable multi-stage injection strategies, where fuel is delivered in multiple pulses during each combustion cycle. In efficiency design, progressed gas shot modern technologies, such as straight injection and port fuel injection, are commonly made use of to achieve particular performance goals.

Report this page